Identify optimization potential through precise OEE measurement

Ernst Sutter AG

The challenge - automating the survey of Overall Equipment Effectiveness (OEE)

Ernst Sutter AG is one of the leading Swiss companies in the meat processing and meat product production sector, headquartered in Gossau, St. Gallen. It produces and supplies fresh meat and meat products for specialist butchers, retailers, wholesalers and the food industry throughout Switzerland at five production facilities and two regional logistics platforms. To optimize the collection of OEE data, the company has decided to work with iDIP Solution.

Implementation with iDIP - PDC with the use of mobile devices, more comprehensive data, new dashboards, direct OEE calculation

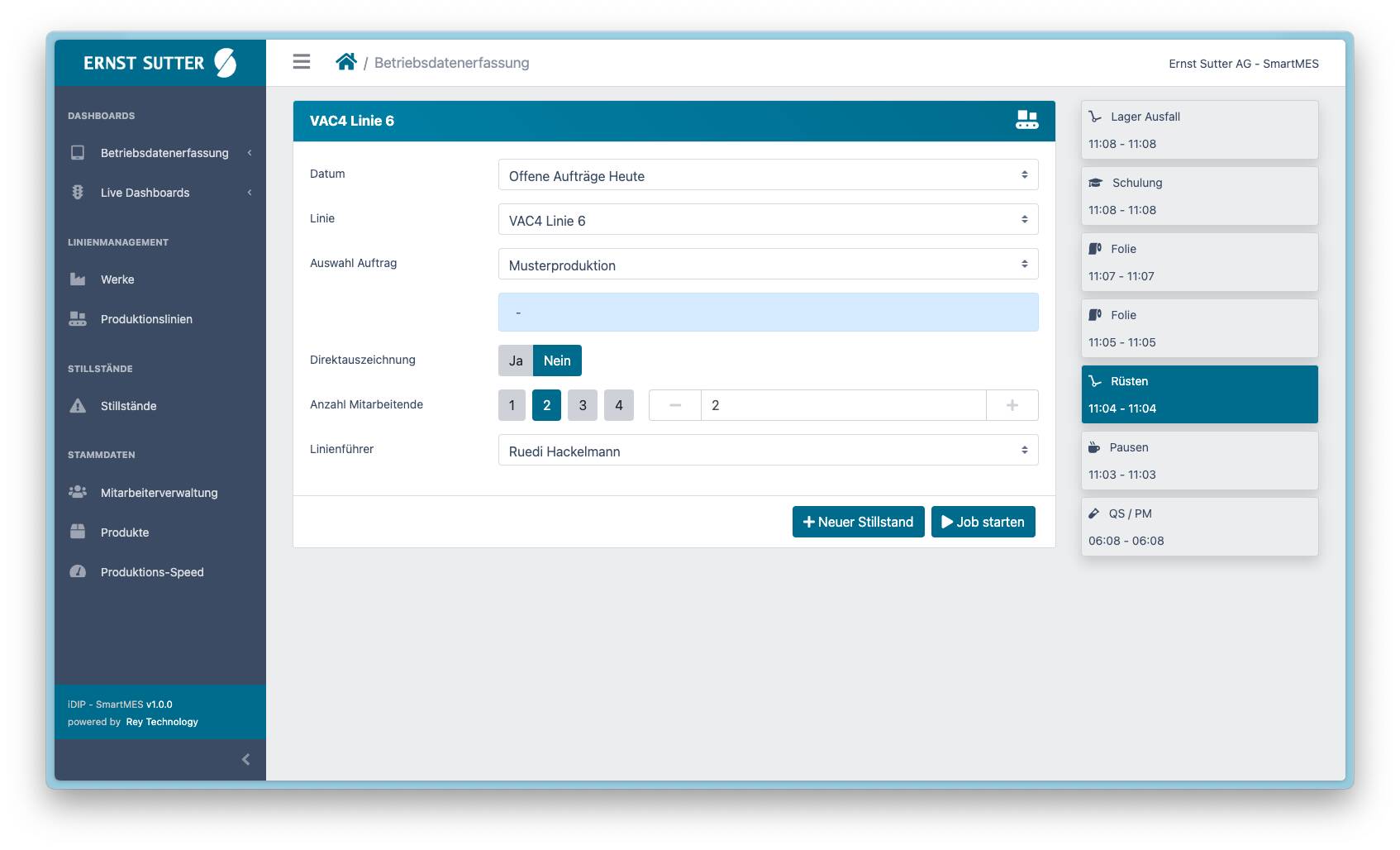

The following functionalities were introduced with the implementation:

- Plant management: 26 plants are currently connected at 4 locations. These connections can be managed in the iDIP.

- Operating data acquisition: The start and stop of an order as well as downtimes can be recorded easily and in a structured manner on mobile devices.

- "Downtime reason recording": If a machine has to be stopped, the reasons for this are recorded in a structured manner on a mobile device.

- Machine connection: The performance data (machine cycle) can be transmitted directly thanks to the machine connection and no longer needs to be recorded/transmitted manually.

- Dashboards: The dashboards show the current machine performance and line status as well as data on the current order on large screens in the production halls.

- Data enrichment: The data is additionally enriched with data from SAP.

- BOEE calculation: The OEE is calculated based on the data in iDIP.

The result - identifying the right measures

Thanks to iDIP, Ernst Sutter AG can track the OEE more precisely and identify efficiency and improvement measures based on this. On the one hand, structured data acquisition, machine connection and data enrichment have increased data quality and minimized sources of error. On the other hand, data collection has become more efficient as less time is required and the manual effort and paper requirements have been greatly reduced. The cycle measurement allows the production controller to compare the actual cycle speed with the planned cycle speed and to identify any deviations immediately. Overall, the production controller has a better overview of production efficiency as the process has become more transparent.

"Thanks to iDIP, we were able to automate the OEE survey across our sites in Eastern Switzerland. This gives us a good overview of the OEE of the various production lines and allows us to initiate measures immediately if necessary."

Stefano Martinetti, Member of the Executive Board of Ernst Sutter AG

Simply get started

Get to know the Smart Factory solution of the future! We would be happy to show you the benefits you can achieve in your company.

Tomy Mändli