End-to-end digitization: Efficient processing of electronic waste

Immark

The challenge - time-consuming paperwork and inaccuracies

Immark is a pioneer and market leader in Switzerland in the disposal and recycling of waste electrical and electronic equipment. founded in 1986, it has been part of the Thommen Group in Kaiseraugst since 2010.

Immark receives the electronic waste from its suppliers. In the past, the production quantities were recorded on paper. This data was then entered manually into various systems for further processing. This process was time-consuming and error-prone. In addition, there was no container tracking and therefore no inventory management. The processed quantities and stock levels were only based on estimates. Problematic, unusable material could no longer be assigned to a supplier due to a lack of options.

The implementation with iDIP - digitized from A to Z

After an intensive initial phase, the collaboration for the digitalization of Immark's specific processes turned into a regular exchange. The following main functions were implemented:

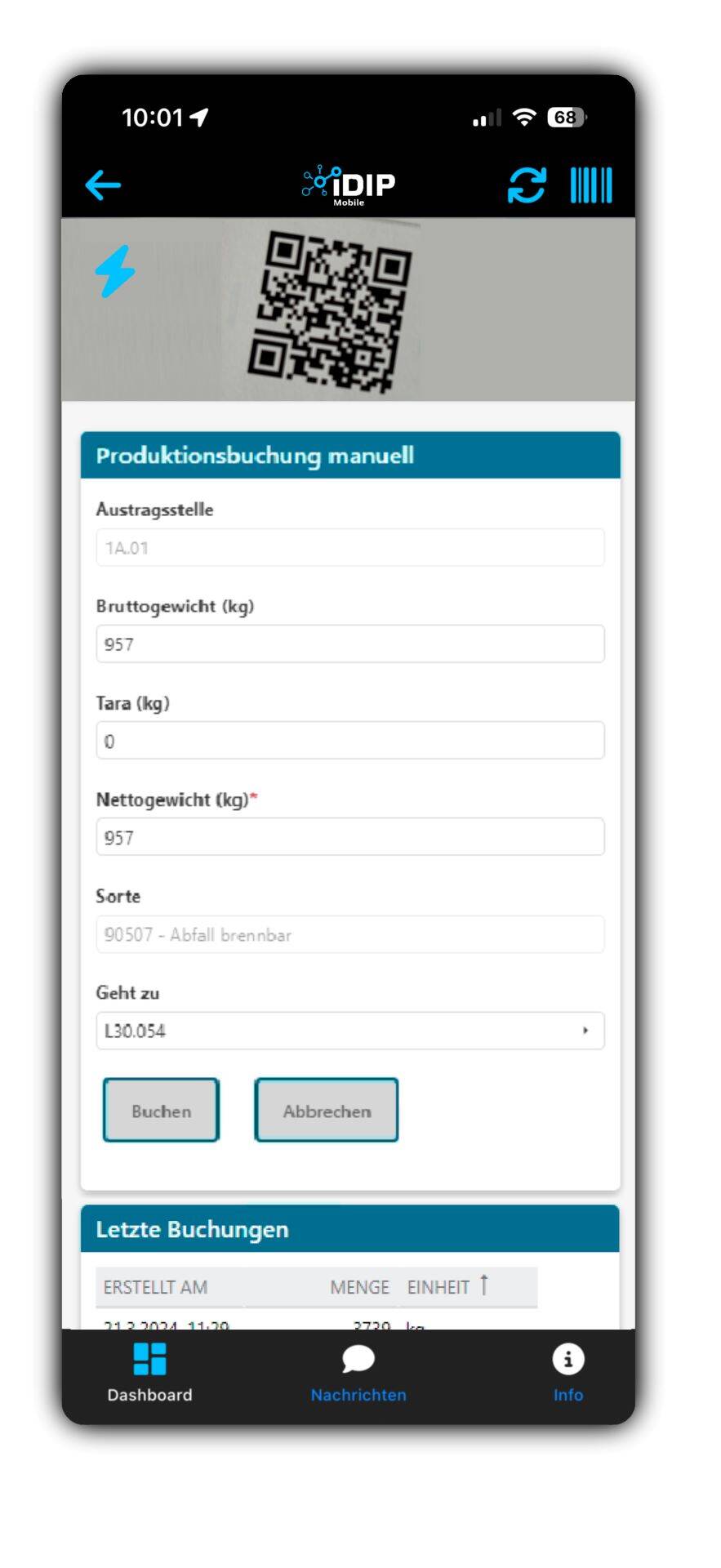

- Recording production data: Manual recording of the quantities produced on paper has been replaced by digital recording with iDIP.

- Package tracking: In future, delivered goods will be provided with a code that can be used to retrieve information such as the date and supplier if required.

- Stock management: Thanks to this container tracking, the data can now be used for automatic stock management. The stock levels are now up-to-date at all times and can be used for forecasting, for example.

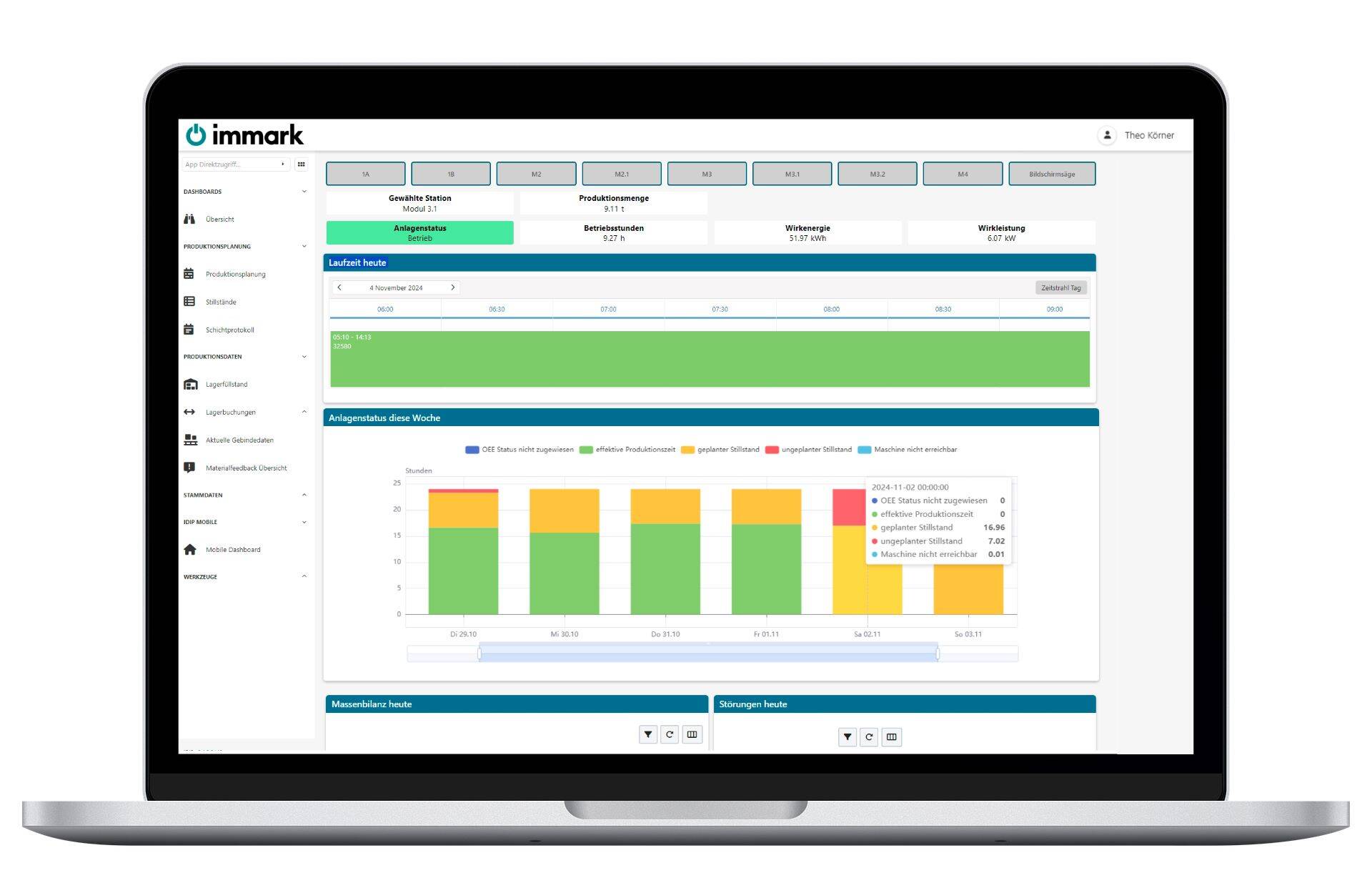

- Machine connection: The machines used for recycling are integrated into iDIP. The available machine data is used, for example, to calculate the OEE value.

- Production planning: In a practical calendar view, the target planning can be evaluated directly against the actual planning based on machine data.

- Dashboards: Production and machine data are visually processed and made available in real time and as a history.

The result - significant simplifications from collection to recycling

Paper has been completely eliminated in production, with the production process now only being handled using mobile devices. In future, the integrated scanner of the iDIP mobile app will be used to scan the containers and assign them directly to a workstation. The production quantities are then recorded digitally via the intuitive user interface. This not only reduces errors and improves data quality, but also reduces the workload.

Thanks to the upcoming container tracking and the resulting automatic warehouse bookings, transparency in warehouse occupancy is increased. Immark can also track deliveries more precisely. The visualization of machine data, which is now available in real time, enables better monitoring of the production process. This reduces downtime and error costs. The higher data quality has improved production planning and increased the accuracy of forecasts.

"Thanks to the flexibility and possibilities of iDIP, we were able to eliminate paper, streamline processes, make production more transparent and inspire our employees. What's more, we now have further development under our own control and are rolling this out across the entire Thommen Group."

Matthias Ebneter, COO Immark AG

Simply get started

Get to know the Smart Factory solution of the future! We would be happy to show you the benefits you can achieve in your company.

Tomy Mändli